Overview

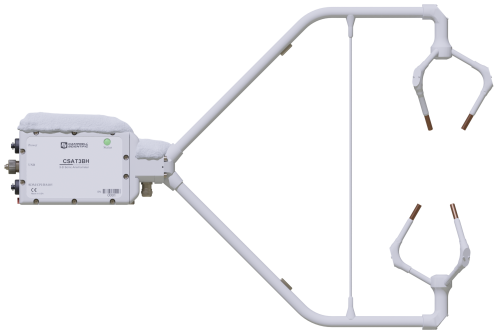

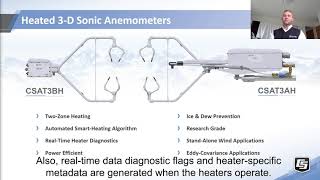

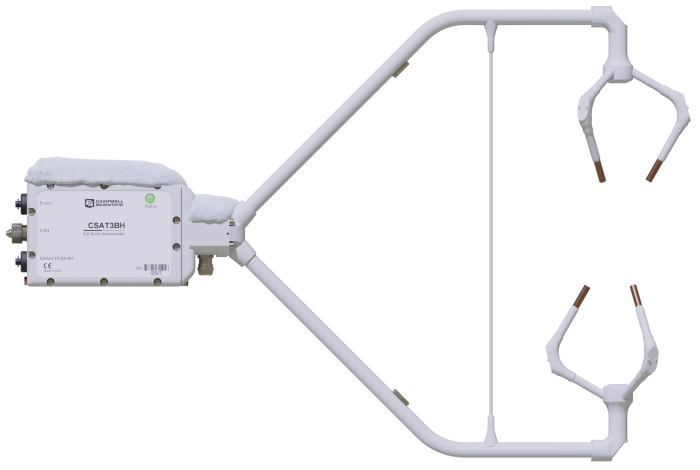

The CSAT3BH is ideal for stations that are deployed in cold climates. The easy-to-use CSAT3BH sonic anemometer features smart heating that delivers just the right amount of heat to keep the instrument free of ice and snow, enabling continuous and reliable measurements in cold environments. The CSAT3BH is designed to prevent ice accumulation on the sensor, avoiding prolonged periods of data loss.

The CSAT3BH features variable power, only delivering power when needed—as opposed to the common method of providing two-way heating (on/off). Moreover, there are real-time data flags when the heaters are turned on, which is crucial to post-processing your data files.

The CSAT3BH is a heated version of the CSAT3B 3-D Sonic Anemometer with Integrated Electronics. The specifications of the CSAT3BH are the same as the CSAT3B with regard to wind measurements.

Read MoreBenefits and Features

- New conformal coating helps protect sonic transducers in corrosive environments

- Two-zone heating to keep both the transducers and body of the sonic anemometer free of snow and ice

- Heating controller using environmental feedback to ensure power budgeting

- Streamlined heater integration to ensure maintenance of sonic aerodynamics

- Integrated data flagging, providing critical information when heaters were operational

Images

Detailed Description

The CSAT3BH provides integrated two-zone smart heating:

- Zone 1 consists of the arms and strut.

- Zone 2 provides heating to all the transducers.

The smart heating uses environmental conditions and a controller to apply variable heating to the sonic anemometer to keep the body and transducers free of ice and snow. The CSAT3BH is designed to prevent ice from forming on the arms and fingers of the system. The block has no heating in it. The CSAT3BH has a separate controller that is used to control the heating algorithm of the sensor. The controller requires a temperature/RH input. There is an ambient temperature and relative humidity sensor that is standard for use with the controller, or the data can be provided through a user-supplied temperature/RH sensor.

Physical

The CSAT3H heater controller is a polycarbonate enclosure sized 20.32 x 25.4 x 15.24 cm (8 x 10 x 6 in.). The enclosure uses connectors for incoming power, heaters, temperature sensors, temperature/RH, RS-485(2), and USB.

Electrical

The heaters are controlled on two zones and require 150 W at full power. The controller controls the heaters by increasing or decreasing the voltage to get the appropriate wattage to keep ice from forming on the sensor.

Similar Products

Specifications

| Sensor | 3-dimensional sonic anemometer |

| Measurement Description | Highest-quality wind speed and direction |

| Operating Temperature Range | -40 to +50°C (equivalent to 305 to 368 m s-1 in speed of sound) |

| Outputs | ux, uy, uz, Ts (ux, uy, uz are wind components referenced to the anemometer axes; Ts is sonic temperature in degrees Celsius.) |

| Speed of Sound | Determined from three acoustic paths. (Corrected for crosswind effects.) |

| Wind Direction Range | 2.5 to 357.5° in CSAT3B coordinate system (0 to 360° customized) |

| Filter Bandwidths | 5, 10, 20, or 25 Hz |

| Measurement Path Length | 10.0 cm (3.9 in.) vertical; 5.8 cm (2.3 in.) horizontal |

| Transducer Angle from Horizontal | 60 degrees |

| Transducer Diameter | 0.64 cm (0.25 in.) |

| Transducer Mounting Arm Diameter | 0.84 cm (0.33 in.) |

| Support Arm Diameter | 1.59 cm (0.63 in.) |

| Anemometer Head Weight | 1.9 kg (4.2 lb) |

| Anemometer Dimensions | 63.1 x 12.3 x 43.3 cm (24.8 x 4.9 x 17.0 in.) |

Power Requirements |

|

| Anemometer Voltage Requirement | 9.5 to 32 Vdc |

| Current Required for 10 Hz Measurement Rate |

|

| Current Required for 100 Hz Measurement Rate |

|

| Heaters | 6.2 A (@ 24 Vdc) |

| Arms and Strut |

|

| Transducer Fingers |

|

| Total System Power |

|

| Controller Current Required | 30 mA (heaters off [quiescent] @ 24 Vdc) |

Wind Accuracy |

|

| -NOTE- |

Accuracy specifications assume the following:

|

| Maximum Offset Error | < ±8.0 cm s-1 (ux, uy), < ±4.0 cm s-1 (uz) |

| Maximum Gain Error |

|

Measurement Resolution |

|

| ux, uy | 1 mm s-1 RMS |

| uz | 0.5 mm s-1 RMS |

| Ts | 0.002°C RMS (at 25°C) |

| Wind Direction | < 0.058° (ux = uy ≤ 1 m s-1) |

Measurement Rates |

|

| Data Logger Triggered | 1 to 100 Hz |

| Unprompted Output (to PC) | 10, 20, 50, or 100 Hz |

| Internal Self-Trigger Rate | 100 Hz |

Measurement Delay |

|

| Data Logger Triggered (no filter) | 1 trigger period (1 scan interval) |

| Unprompted Output (no filter) | 10 ms |

| Filtered Output (data-logger-prompted or unprompted to PC) |

|

Internal Monitor Measurements |

|

| Update Rate | 2 Hz |

| Inclinometer Accuracy | ±1° |

| Relative Humidity Accuracy |

|

| Board Temperature Accuracy | ±2°C |

SDM |

|

| -NOTE- | Used for data-logger-based data acquisition. |

| Bit Period | 10 µs to 1 ms |

| Cable Length |

|

| Address Range | 1 to 14 |

| Bus Clocks per Sample | ~200 |

CPI |

|

| -NOTE- | Used for data-logger-based data acquisition. |

| Baud Rate | 50 kbps to 1 Mbps |

| Cable Length |

|

| Address Range | 1 to 120 |

| Bus Clocks per Sample | ~300 |

RS-485 |

|

| -NOTE- | Used for anemometer configuration or PC-based data acquisition. |

| Baud Rate | 9.6 kbps to 115.2 kbps |

| Cable Length |

|

| Bus Clocks per Sample | ~500 (ASCII formatted) |

USB |

|

| -NOTE- | Used for anemometer configuration or PC-based data acquisition. |

| Connection Speed | USB 2.0 full speed 12 Mbps |

| Cable Length | 5 m (16.4 ft) maximum |

Related Documents

Manuals

Technical Papers

Videos & Tutorials

Downloads

CSAT3BH CR1000X Programs v.2.03 (9 KB) 20-11-2020

CR1000X datalogger programs for the CSAT3BH with SDM and CPI communications protocols.

Warning: This program is not intended for the CSAT3H Heater Controller Enclosure. Please contact Campbell Scientific for any questions regarding the CSAT3H Heater Controller program.

CSAT3BH CR6 Programs v.2.03 (9 KB) 20-11-2020

CR6 datalogger programs for the CSAT3BH with SDM and CPI communications protocols.

Warning: This program is not intended for the CSAT3H Heater Controller Enclosure. Please contact Campbell Scientific for any questions regarding the CSAT3H Heater Controller program.

CSAT3H Heater Controller v.14.2 (46 KB) 02-02-2021

The CSAT3H Heater Controller ships with this encrypted program. This program is for the unlikely event that the program needs to be re-installed or updated to a newer version. Please contact Campbell Scientific if you have questions about the program or would like the algorithm modified for a specific application.

FAQs for

Number of FAQs related to CSAT3BH: 15

Expand AllCollapse All

-

Yes. The CSAT3B and CSAT3BH measurement frequency can be changed by the user. The user can either choose a prompted or unprompted output rate. The prompted output rate is based on the scan interval of the data logger, which must be an integer. Therefore, the measurement frequencies supported would be 1, 2, 4, 5, 8, 10, 20, 25, 40, 50, and 100 Hz. The unprompted output rate allowed is 10, 20, 50, and 100 Hz.

-

Ultrasonic anemometers are unable to make measurements if the sonic path is blocked. The path may become blocked by water that puddles on the lower transducer face or droplets that hang from the upper transducers. Sonic wicks, which come with all sonics, can be placed on the transducers to wick away moisture from the faces of the transducers. Ensure that these wicks are removed during cold conditions to prevent ice from building up around them.

-

The sonic anemometer offset specification is ±8 cm/s. Therefore, it cannot be used in an application where the expected wind speed is in the range of ±5 cm/s.

-

The sonic anemometer measures three-dimensional wind in a right-handed Cartesian coordinate system. From these measurements, use trigonometry to compute the wind flow angle, horizontal angle, and wind speed.

-

No. The sonic anemometer does not report time with the wind measurements. A time stamp will be assigned to the wind data by the data-acquisition system—either a data logger or a PC.

-

Yes. If the matching layer is damaged or missing, return the sonic anemometer to the factory for repair. Follow the steps listed on our Repair and Calibration page to request a return material authorization (RMA) number.

-

Campbell Scientific does not offer any mounting booms or hardware that enable easy and frequent positioning of the sonic anemometer sensor head. This type of hardware must be provided by the user.

-

The CSAT3A, CSAT3AH, CSAT3B, and CSAT3BH are calibrated over temperature for the effects of transducer delays on the wind speed, and to a lesser extent, for the speed of sound measurements.

There is no NIST-traceable standard for ultrasonic anemometers.

-

No. The offset is a function of temperature and time. Once a year, spot-check the sonic anemometer wind offset using the procedure outlined in the CSAT3B instruction manual. If the measured offset is outside the specification, return the sensor to the factory for calibration. To request a return material authorization (RMA) number, follow the steps listed on our Repair and Calibration page.

-

The CSAT3A, CSAT3AH, CSAT3B, and CSAT3BH—like other sonic anemometers—measure wind speed along the sonic path using ultrasonic signals. If the salt spray blocks the sonic path, the sonic anemometer will not be able to make measurements. The same is true if a thick layer of salt is deposited on the transducer faces.