| Services Available | |

|---|---|

| Repair | No |

| Calibration | No |

| Free Support | No |

Overview

The CR206 Datalogger features an on-board 900 MHz spread-spectrum radio with the functionality of the CR200 Datalogger. The CR206's input channel configuration and small size is optimal for measuring one or two sensors.

When paired with an ENC200 enclosure and the small 16869 battery, the packaged CR206 has a deployment size of only 6 in. by 7 in. This small package is optimal for the CR206 to be used as a wireless sensor within a PakBus network. The CR206 measures the sensors attached to it, then transmits its data wirelessly via its spread-spectrum radio to a master data logger. For more information on how to configure a PakBus system, please read our PakBus Networking Guide in the Related Documents section.

If an alternate spread-spectrum radio is required, see our CR211 and CR216 dataloggers.

Benefits and Features

- Ideal where only a few sensors will be measured

- On-board 12 Vdc lead acid battery charger

- Stores 128,000 data points (nonvolatile)

- Data format is table-based

- Replaces the CR205 datalogger

Images

Compatibility

Campbell Scientific’s SDM devices and multiplexers are not supported.

Sensors

The CR206 cannot make differential measurements and is not compatible with thermocouples, our geographic position sensor, fuel moisture/temperature probe, and soil heat flux sensors. However, it can measure a variety of sensors including SDI-12 sensors and 4 to 20 mA sensors. Our CS625 Reflectometer, 109 Thermistor, and CS15 Electric Current Sensor were specifically developed for our CR200-series dataloggers. Other compatible sensors include wind sets, tipping buckets, and barometers. For a complete list of compatible sensors, see the CR200-series brochure.

Communications

The CR206 can communicate with a PC via direct connect, NL100 Ethernet interface, MD485 multidrop modem, and our digital cellular modems. Data can be viewed on the CD295 DataView II display or a PDA (PConnect or PConnectCE software required).

The CR206's internal spread spectrum radio can transmit data to other CR206 loggers or RF401 spread spectrum radios. Certain CR206 settings must match the RF401 settings for communications between the data logger and radio to be successful. The factory default settings of these devices do not match; therefore, they must be reconfigured before communications can take place. Refer to the following application note for more information.

Quick Reference Guide for Setting Up RF401-to-CR206 Communications

If the CR206 is in the transparent mode, it can communicate with the retired CR205 loggers or RF400 radios.

Enclosures

Applications with minimal power requirements can use the ENC200 enclosure to house the data logger and the #16869 sealed rechargeable battery. The ENC200 cannot house a barometer or a battery that is larger than the #16869. However, an ENC10/12 or ENC12/14 enclosure is adequate for most CR206-based systems.

Power Supplies

When connected to the on-board charging circuit, the sealed rechargeable battery should be 7 Ahr or smaller. Using larger batteries with the data logger's built-in charger may result in excessive PC board heating. This is especially a concern when the battery is deeply discharged or failing with a shorted cell. Campbell Scientific also recommends that solar panels be 10 W or less and wall chargers be 1 A or smaller.

Compatible software

- Short Cut

- PC200W

- PC400 (version 1.0 or higher)

- LoggerNet (version 2.1 or higher)

- PConnect (version 3.0 or higher)

- PConnectCE (version 2.0 or higher)

- VisualWeather (version 2.0 or higher)

Before March 2005, a CD was shipped with PakCom PC software and PakBus ActiveX (OCX). Effective, 3 March 2005, our DevConfig, PC200W, and Short Cut packages began to include support for the CR200-series dataloggers. These programs are available for download from our website or are on our ResourceCD.

Specifications

| -NOTE- | Note: Additional specifications are listed in the CR200-Series Specifications Sheet. |

| Internal Radio Operating Frequency Range | 910 to 918 MHz |

| A/D Converter | 12 bit |

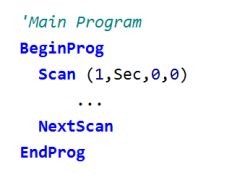

| Scan Rate | Once per second (maximum) |

| Single-Ended Analog Channels | 5 (individually configured) |

| Analog Voltage Range | 0 to +2500 mV |

| Measurement Resolution | 0.6 mV |

| Excitation Channels | 2 (programmable for either +2.5 or +5 volts) |

| Switched Battery Port | 1 |

| Pulse Count Channels | 2 |

| Control Ports | 2 |

| Battery Voltage Range | 7 to 16 Vdc |

| Communications | RS-232 |

Related Documents

Technical Papers

Videos & Tutorials

Downloads

CR200 Default OS v.10 (1.97 MB) 08-09-2010

Default operating system loaded into the datalogger at the factory. Also included is the Compiler and CRBasic Editor support files for the CR2xx dataloggers.

Use of this file will update the datalogger compiler and CRBasic Editor support files.

Includes: ETo, WindVector, LoggerIdentify

Excludes: GOES Instructions, SDI12Sensor, SerialInput, MODBUS Instructions, SendData

CR200 MODBUS OS v.10 (1.97 MB) 08-09-2010

Special operating system that supports ModBus communication and SDI-12 sensors . Also included is the Compiler and CRBasic Editor support files for the CR2xx dataloggers.

Use of this file will update the datalogger compiler and CRBasic Editor support files.

Note: Not to be used with the CR200X series.

Includes: MODBUS Instructions, SDI12Sensor, WindVector

Excludes: GOES Instructions, SerialInput, ETO, SendData, & LoggerIdentify

CR200 Serial Input OS v.10 (1.97 MB) 08-09-2010

Special operating system that supports serial sensors, SDI-12 sensors, and sending data to another PakBus device. Also included is the Compiler and CRBasic Editor support files for the CR2xx dataloggers.

Use of this file will update the datalogger compiler and CRBasic Editor support files.

Includes: SerialInput, SendData, SDI12Sensor, WindVector

Excludes: GOES Instructions, ETo, MODBUS Instructions, LoggerIdentify

FAQs for

Number of FAQs related to CR206: 1

-

A practical maximum is to connect one multiplexer per every two control terminals on the data logger. Control terminals can be shared between multiplexers to increase the number of connected multiplexers. Sharing terminals, however, requires more complex wiring and programming. Users who would like to connect more than one multiplexer per every two control terminals are advised to contact a sales or support engineer at Campbell Scientific for assistance.